Unveiling “Zero Porosity Management” by Rahat A Bhatia: A Transformational Die-Casting Guide

Are you ready to embark on a transformative journey in the world of die casting? Allow us to introduce you to “Zero Porosity Management” by the renowned author, Rahat A Bhatia. In this blog post, we’ll explore the core concepts of the book and shed light on how this innovative approach can revolutionize your die-casting business.

Zero Porosity: Myth or Reality?

Zero porosity—it sounds like an unattainable dream, doesn’t it? In the realm of die casting, achieving absolute zero porosity is indeed a myth. Rahat A Bhatia’s book makes it clear from the outset: zero porosity is not a realistic goal. But don’t be disheartened; there’s a practical approach to mitigate porosity and improve your casting quality.

In the context of “Zero Porosity Management,” when we mention zero porosity, we’re referring to the pursuit of porosity levels nearing zero, though never reaching absolute zero. The book delves into the strategies and techniques to make this goal a reality.

Introducing Zero Porosity Management (ZPM)

ZPM, introduced for the first time in this book, is a groundbreaking concept never before implemented in die-casting companies. It’s not just a management program; it’s a holistic approach to defining and maintaining input parameters in die-casting environments. ZPM’s ultimate goal is to achieve casting quality with near-zero porosity.

Here’s what ZPM can achieve for your die-casting business:

- Minimize losses and increase profits: ZPM is your ticket to a more efficient and cost-effective die-casting process.

- Reduced dependency on skills: Say goodbye to the unpredictability associated with skill-dependent processes.

- Improved shop floor operations: Experience fewer breakdowns, longer mold life, reduced rejections, and increased productivity.

- Monitoring, control, and prediction: ZPM ensures that every aspect of your die-casting process is systematically managed and optimized.

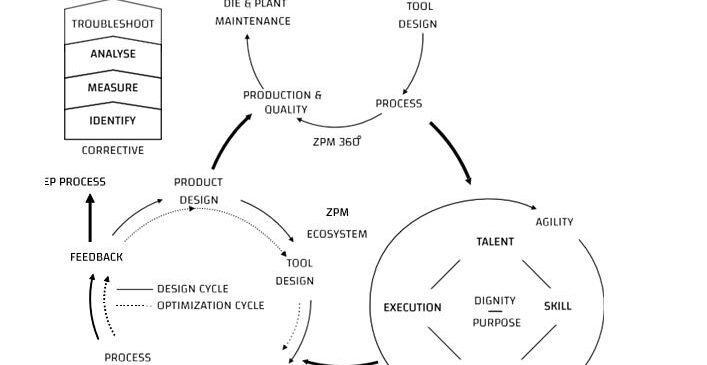

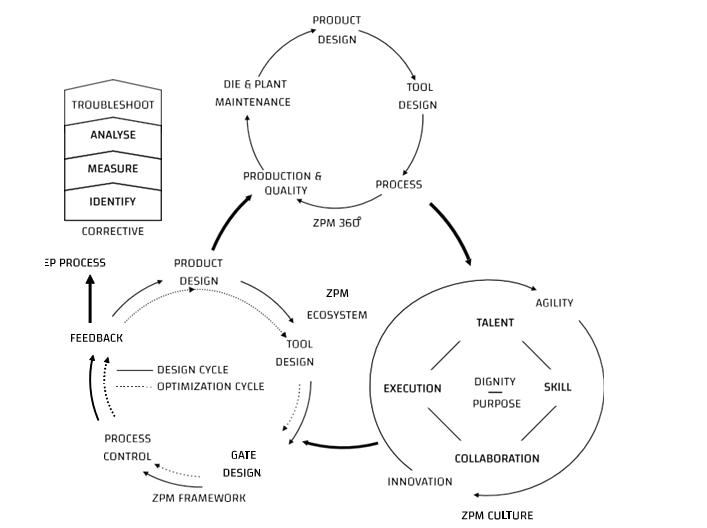

The ZPM Ecosystem

The ZPM ecosystem comprises a design and optimization framework with a corrective and preventive feedback mechanism, a 360-degree approach, and a culture charter. It’s a comprehensive system designed to nurture a framework, structure, and culture that leads to minimal porosity in your castings.

Integration with Existing Management Practices

If you’re already implementing concepts like Total Quality Management (TQM), Total Preventive Maintenance (TPM), or Lean practices in your manufacturing setup, you’ll find ZPM to be a valuable addition. While ZPM is a subset of TQM, it’s tailored specifically for the die-casting industry, making it a natural progression in your journey towards operational excellence.

Understanding Porosity Sources

To effectively control porosity, it’s essential to grasp its sources. In high-pressure die casting (HPDC), the two primary sources are shrinkage and trapped gas. Shrinkage occurs during the cooling and solidification of molten metal, while trapped gas can originate from various sources like the die-casting cavity, shot sleeve, and die lubricants.

Myth vs. Reality: Demystifying Porosity

Porosity is often misconstrued as a defect. However, it’s crucial to understand that not all castings with porosity are defective. Porosity only becomes an issue when it compromises the casting’s intended functionality. This book unravels the truth about porosity, its causes, and how to effectively manage it.

What’s Next?

Stay tuned for upcoming blog posts that will delve deeper into the principles and practices outlined in “Zero Porosity Management” by Rahat A Bhatia. Learn how to implement ZPM, discover the tools and strategies for minimizing porosity, and witness the transformation of your die-casting business.

Order Your Copy Today and take the first step toward mastering “Zero Porosity Management”!

Are you ready to transform your die-casting business and enhance casting quality? Let “Zero Porosity Management” be your guide on this exciting journey.

Please let us know if you’d like to explore specific chapters or topics in more detail for SEO purposes.