Unlocking Die Casting Excellence with Rahat A Bhatia’s “Zero Porosity Management”

Die casting, the process of creating complex metal parts with precision, has long been a cornerstone of various industries, from automotive to aerospace. However, one persistent challenge has plagued die casters throughout the years: porosity. In his groundbreaking book, “Zero Porosity Management,” author Rahat A Bhatia delves deep into the world of die casting, revealing innovative technologies and AI solutions that are revolutionizing this critical industry. This blog post aims to provide insights into the book’s key chapters, ensuring that both the book and the author gain the recognition they deserve.

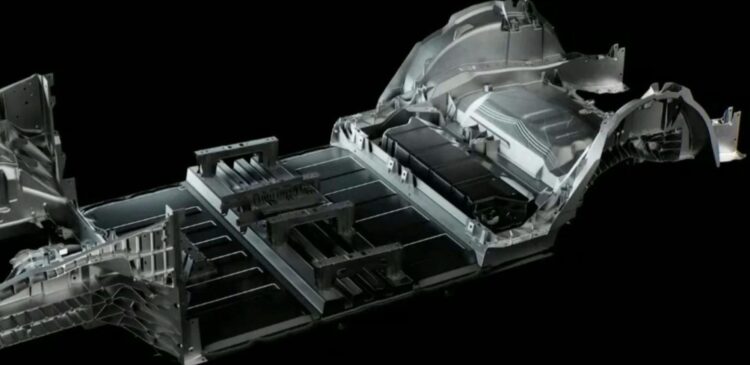

New Technology Solutions: Revolutionizing Die Casting

In the quest for zero porosity, die casters are embracing cutting-edge technology solutions that promise greater control and reduced porosity levels. This chapter explores the ongoing academic research and development efforts in key die-casting companies. They are pioneering new ways to gather critical information, allowing for in-depth analysis and insights through traceability.

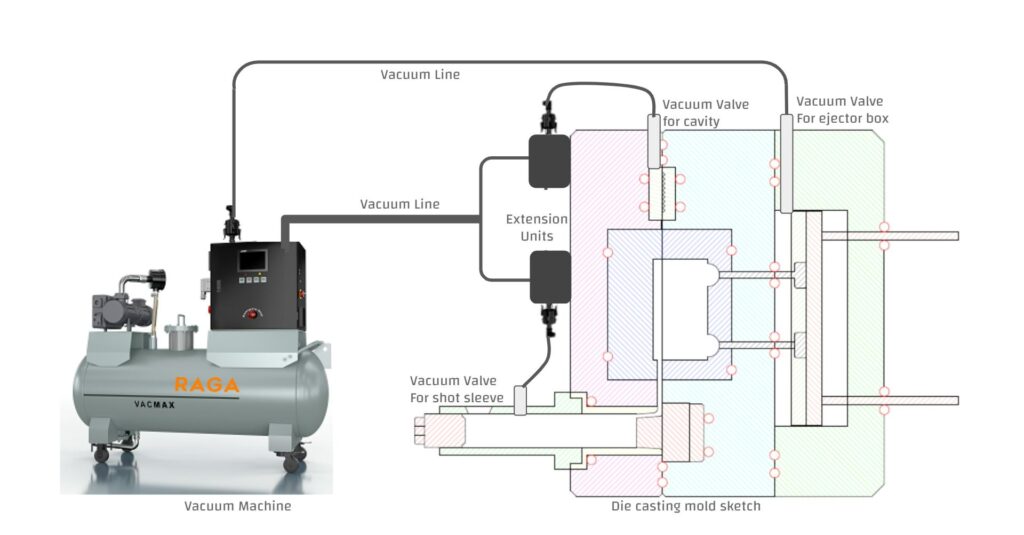

High Vacuum Technology: A Key Player

A typical layout of twin stage vacuuming+ Modular +High vacuuming

A typical layout of twin stage vacuuming+ Modular +High vacuuming

High vacuum technology has become instrumental in reducing gas porosity in castings. Over time, this technology has evolved significantly. Notable advancements include twin-stage vacuuming, high vacuuming for critical and safety-sensitive castings, and modular vacuuming solutions. These innovations enhance shot velocity consistency, reduce resistance, and meet stringent porosity requirements.

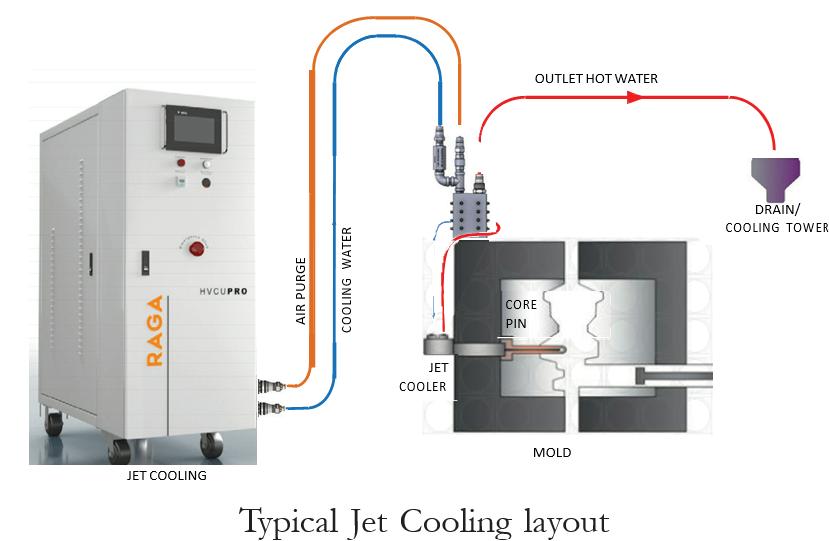

Jet Cooling: Beyond Core Pins

Originating in Japan, jet cooling has evolved to address various challenges beyond core pins. It now plays a crucial role in cooling thin inserts, improving the cooling of hot zones, and enhancing casting strength through solidification pattern changes. Recent developments include closed-loop jet cooling, which recirculates water to save resources, and advanced monitoring systems that provide real-time data for prevention and troubleshooting.

Originating in Japan, jet cooling has evolved to address various challenges beyond core pins. It now plays a crucial role in cooling thin inserts, improving the cooling of hot zones, and enhancing casting strength through solidification pattern changes. Recent developments include closed-loop jet cooling, which recirculates water to save resources, and advanced monitoring systems that provide real-time data for prevention and troubleshooting.

Semisolid Metal Casting: Precision and Low Porosity

Semisolid metal casting offers exceptional accuracy and low porosity for complex products. This process injects metal in a pasty or slurry state, ensuring even cooling and reducing surface tearing. Thixoforming and rheocasting processes take advantage of the solidus and liquidus temperature range to minimize casting defects like micro-segregation, shrinkage, and porosity.

Semisolid metal casting offers exceptional accuracy and low porosity for complex products. This process injects metal in a pasty or slurry state, ensuring even cooling and reducing surface tearing. Thixoforming and rheocasting processes take advantage of the solidus and liquidus temperature range to minimize casting defects like micro-segregation, shrinkage, and porosity.

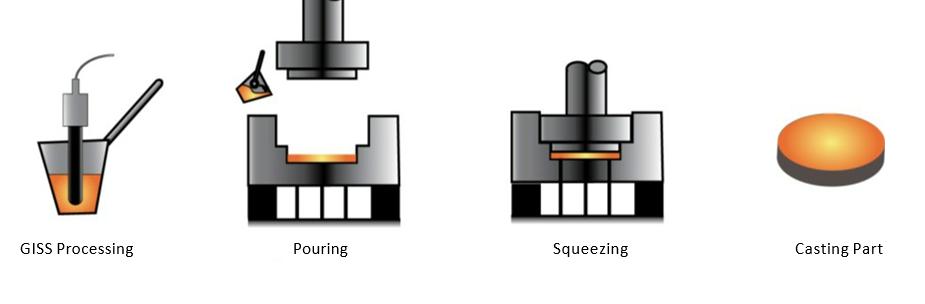

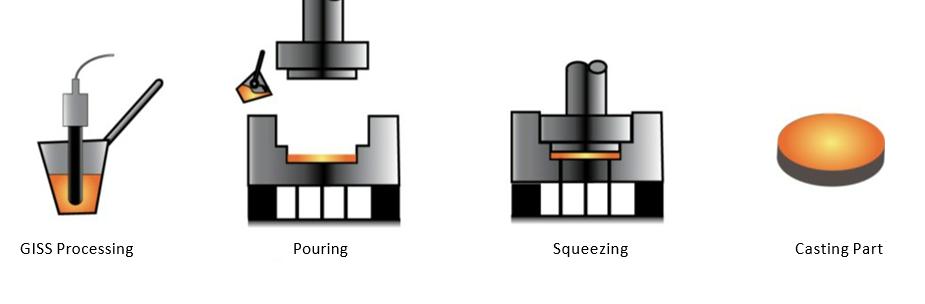

Gas Induced Semi Solid Slurry Casting: A Promising Alternative

Gas-induced semi-solid slurry casting is a promising technology for reducing entrapped gas and shrinkage porosity defects. This method prepares and casts superheated slurry, allowing the use of various alloys with existing dies, without extensive modifications. It significantly reduces defects while extending die life and reducing cycle times.

Gas-induced semi-solid slurry casting is a promising technology for reducing entrapped gas and shrinkage porosity defects. This method prepares and casts superheated slurry, allowing the use of various alloys with existing dies, without extensive modifications. It significantly reduces defects while extending die life and reducing cycle times.

TiA – the AI Technology for Die-casting: The Future of Excellence

Enter TiA, an industrial AI (Artificial Intelligence) developed by Tvarit GmbH, a German company. TiA represents a paradigm shift in die casting. Unlike conventional AI models that rely on statistical data, TiA replicates the reality of shopfloor processes. It considers diverse variables, including geometry, materials, maintenance, and ambient conditions. TiA integrates data from IoT sensors, such as temperature and pressure, to predict porosity defects and even alerts operators to deviations in process parameters. Its robustness and ROI-focused approach make it a game-changer for die casting companies.

Join the Movement Towards Excellence

“Zero Porosity Management” by Rahat A Bhatia is a treasure trove of insights into the world of die casting. With its exploration of cutting-edge technologies and AI solutions, this book charts a course toward achieving zero porosity and unlocking die casting excellence.

Get Your Copy of this enlightening book and be part of the movement to revolutionize the die casting industry. Stay tuned for more insights and practical tips for elevating your die-casting processes and ensuring the highest quality standards.