Unearthing Porosity Management Challenges: Insights from Rahat A Bhatia’s Book

In a book of Rahat A Bhatia’s , “Zero Porosity Management,” we delve into the intricate world of porosity management within the die-casting industry. Porosity, a perennial concern, often leaves manufacturers grappling with product rejections and profitability issues. Rahat A Bhatia, drawing from his extensive experience, illuminates the challenges and evolving standards in this vital aspect of die casting.

Author Spotlight:

Rahat A Bhatia: Before we immerse ourselves in blog, let’s reacquaint ourselves with the visionary author, Rahat A Bhatia. With nearly three decades of die-casting expertise, Bhatia has emerged as a guiding light in the industry, reshaping practices and perspectives.

Book Overview: in the book offers an insightful exploration of porosity management challenges faced by die-casting professionals. Rahat A Bhatia addresses the significance of minimizing porosity and the implications for the industry:

The Porosity Predicament:

Have your products faced rejection due to excessive porosity, impacting your business’s bottom line? If so, this chapter is a must-read. Rahat A Bhatia commences by highlighting a pivotal 2010 survey by the North American Die-Casting Association (NADCA). Astonishingly, 35% of respondents identified porosity as their primary concern, with another 32% citing “other defects” often interconnected with porosity-related issues.

Porosity’s Impact:

Porosity’s implications are far-reaching. It directly affects profitability, demands stringent quality adherence from end customers, necessitates thinner walls and intricate castings in light weighting initiatives, and even impacts product aesthetics. With the rise of electric vehicles, porosity becomes a critical concern for automotive companies, influencing the acceptance or rejection of parts and, consequently, gains or losses.

Is It the Problem or Its Management?

While porosity remains a significant challenge, Rahat A Bhatia raises a fundamental question: Is the issue truly porosity itself or rather the management of porosity? Often, the responsibility of porosity management rests on a select group of experts and engineers, leaving many die-casters grappling with this persistent problem.

Rising Standards: Porosity standards are evolving, with OEMs demanding more rigorous adherence. The stringent specifications are a response to factors such as avoiding potential failures, improving designs based on Failure Mode Effect Analysis (FMEA), ensuring consumer safety, complying with regulatory requirements, mitigating the expensive fallout of product recalls due to porosity issues, enhancing product durability, pursuing Value Analysis and Value Engineering (VAVE), and competing on quality.

Competitive Edge: Business within the die-casting industry is relentless. Companies must either meet contemporary quality standards or risk losing their competitive edge. Rahat A Bhatia recounts a real-life scenario where an Asian die caster lost a significant share of business to a Turkish counterpart due to porosity-related quality standards.

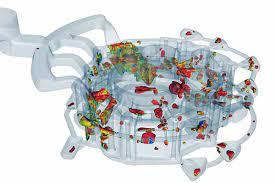

The Complexity of Variables: Die-casting is fraught with variables encompassing design, process, and environmental factors, all significantly influencing quality and productivity. Managing these variables is essential for controlling porosity, but it remains a complex undertaking, often leading to breakdowns and challenges on the shop floor.

The Learning Curve: Porosity management requires skill, knowledge, and experience. Die casters embark on a long learning curve to master the intricacies of handling high-margin critical parts. This journey can be perilous, with businesses at risk of losses and even closures due to fierce competition and rapidly evolving specifications.

Shortening the Learning Curve: As the industry faces constant change and rising customer expectations, the question arises: Can the lengthy learning curve be shortened? Rahat A Bhatia prompts us to explore whether porosity management can be made more modular and scalable, ensuring the transferability and sustainability of critical skills.

This chapter peels back the layers of porosity management, offering profound insights into a challenge that resonates deeply with die casters worldwide. Rahat A Bhatia’s wisdom illuminates the path forward in an industry where excellence is the only option.

Stay tuned as we journey further into “Zero Porosity Management” and uncover more gems of knowledge from Rahat A Bhatia’s remarkable book.