| Engine block | Bed plate |

| Cam carrier | Rocker arm |

| Cooler cover | Timing case cover |

| ETB Housing | Clutch cover |

| Crankcase | Case oil pan |

| Transmission case / Housing | TransAxle |

| Filter housing | Brake oil cover |

| Battery Case / Housing | Battery charger Case / Housing |

| Converter housing | Controller housing |

| Motor housing | Pump & Valve parts |

| Air conditioning parts | Shock absorption parts |

| Structural parts | Telecommunication parts |

| and many more.. |

Reduces shrinkage & porosity

Minimises pressure leakage

Reduces scrap

Eliminates drilling & finishing

Decreased soldering & erosion of core pins

Enhances life of die parts

Allows handling of hot spots

Reduces mold maintenance & machine downtime

Increases mold life time

Brands you as a high technology caster

Ahead of competitors

Enables you to develop critical part

Readiness for high margin parts

Water Temperature & TDS controller for Jet, Spot & Line cooling.

Close loop your existing or new Jet cooling machine.

Save water consumption cost and improve efficiency of mold cooling.

Reduce scaling in cooling line and improve casting quality

Jet cooling machine by raga is a proven & reliable technology for minimizing shrinkage porosity in thin sections & around core pins in a die-cast part.

Casters trust this plug & play jet cooling machine due to its optimal cost-performance & almost nil maintenance. Jet cooling equipment works with jet coolers and core pins in the mold to reduce soldering & shrinkage porosity. The jet cooling machine conforms to international standards & spares.

Raga NEX is one of the widely used variants in its range of jet cooling machines.

PRO is an entry level Jet Cooling machine, one of the first from Raga. This comes for 20 pins and 2 systems configuration.

Simple and effective machine to reduce shrinkage porosity in castings. It has served die casters in India majorly since more than 10 years now.

This machine is good for smaller molds. It’s a low maintenance and service cost machine. Again easy to install and works with any die casting machine.

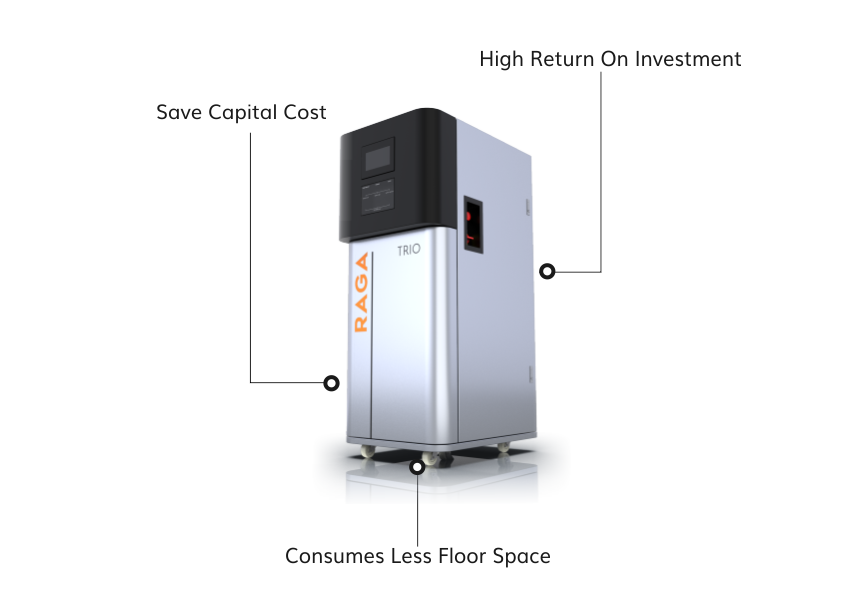

We call it TRIO, world’s first Centralized jet cooling machine. Integrates with up to 3 Die casting machines simultaneously.

Modern & sleek looks.

Machine gives high return on investment & consumes less floor space.

Save capital costs when you need jet cooling on smaller HPDC machines.

Buy 1 instead of 3.

Introducing Process controlled Jet Cooling for Mega Castings on High Tonnage Die Casting Machines

Porosity challenges in mega casting are critical and need a highly specialised technology

For die casters who wish to take their game to unbeatable next levels

Large (upto 10) systems or recipes for different heat zones

Inbuilt temperature control & Scale free system making it truly CLOSED LOOP. Also minimising blockage in lines

Compatible* for detection of leakage, blockage and breakage of each core pin

* Monitoring system can be integrated

Brings traceability and predictability in Jet, Spot & Line Cooling.

Standalone unit mounted near or on Platen to monitor output water

Predict failures like blockage, breakage & leakage for individual core pin and cooling line.

Can be installed with any existing Jet Cooling system

Graphical representation for traceability every shot

One stop solution for Jet, Spot & Line cooling

Modular Cell innovation for improved process, traceability and predictability

Temperature controlled closed loop system

Predict failures like blockage, breakage & leakage for individual core pin and cooling line

Graphical visualisation of output per shot

#1 Giga casting cooling solution

Flexibility for large number of systems or recipes

Water trapped in molten aluminium (660 ˚C) can expand 4400 times. The explosion energy of 10 kg TNT roughly corresponds to the explosion energy of 1 kg hydrocarbon. Explosion due to water in molten metal is hazardous and it is critical to prevent water from entering the molten metal.” As per an Italian Association of chemical engineering report in 2019

On breakage of the core pin, highly pressurised water can splurge into molten aluminum undergoing solidification. In one such accident in a die casting plant in the USA, it had serious loss of life and assets.

Die casting is a manufacturing process used to produce metal alloy parts by injecting molten metal alloys under pressure into a reusable steel mold called a die. The molten metal is injected into the die cavity, which has a specific shape and size, and then rapidly cooled to solidify the metal. Once the metal has solidified, the die is opened and the part is ejected.

Porosity is a major cause of rejection in die-casting. Porosity majorly have two types

1. Gas Porosity: Gas porosity is the most common type of porosity in die casting. It occurs when gas, such as air or trapped volatiles, becomes trapped within the molten metal during the solidification process. Gas porosity can manifest as small spherical voids or interconnected gas channels within the part. To control and minimize gas porosity use vacuum technology in die casting.

2. Shrinkage Porosity: Shrinkage porosity is caused by the shrinkage of the molten metal as it cools and solidifies. It typically occurs in areas of thicker sections or where the metal experiences rapid solidification. Shrinkage porosity appears as irregularly shaped voids or cavities in the part. Jet cooling is the best method to reduce shrinkage porosity in die casting.

Jet cooling system is a cooling technique that uses high-pressure water to cool the core pin or insert of die casting during the solidification of casting. After water flow, pressurized air is purged to remove water droplets.

Benefits of Jet Cooling in Die Casting

Improved part quality: Jet cooling can help to reduce the formation of Die casting defects such as shrinkage porosity and soldering. By cooling the core pins and insert quickly, jet cooling can prevent the formation of these defects.

Reduced cycle time: Jet cooling can help to reduce the cycle time of the die-casting process. By cooling the die and the casting quickly, the casting can be ejected from the die more quickly, allowing for a faster cycle time and increased production efficiency.

Longer core pin and insert life: Jet cooling can help to prolong the life of the die. By cooling the core pin and insert quickly, jet cooling can help to prevent washout and other forms of damage to the die.

Energy efficiency: Jet cooling can be more energy efficient than other cooling methods. By using high-pressure water, jet cooling can cool the die and the casting more quickly and with less energy.

Application: Initially, jet cooling was used to cool core pins to reduce shrinkage porosity around core pins and soldering and wear out of pins.

Now the technology has gone beyond core pins. Now jet cooling is also being used for thin inserts that cannot be cooled by spot cooling. It is used with conformal cooling to increase the cooling impact on hot zones. Some die casters also use jet cooling to increase the strength of the casting through solidification pattern changes

Jet cooling can be used in a variety of die-casting processes, including high-pressure die casting, low-pressure die casting, and gravity die casting.

Jet cooling has gone through the following developments recently.

Transform your die-casting processes with the cutting-edge closed-loop jet cooling technology. Harness the power of water recycling within the mold to unlock substantial savings in treated water costs. Our closed-loop jet cooling system, equipped with advanced conductivity measurement and real-time correction capabilities, guarantees optimal water quality, effectively mitigating issues like scaling, blockages, and breakdown maintenance.

Whether you are implementing closed-loop jet cooling in a new setup or upgrading an existing one, Raga AquaControl is your go-to solution. Our system seamlessly integrates with both new and existing jet cooling configurations, offering a unified closed-loop jet cooling experience. What sets Raga AquaControl apart is its built-in temperature control and water quality control system, ensuring precision and efficiency at every step of the die-casting process. Elevate your die-casting operations with Raga AquaControl’s state-of-the-art technology for unmatched performance and reliability.

The monitoring system is the latest development that brings traceability and predictability into the HPDC jet cooling process, our monitoring system ensures real-time data collection, preventing disruptions like leakage, blockages and breakages.

The Raga system, available in 8 or 16-pin HPDC variants, serves as a cornerstone for efficient die-casting, triggering alarms and halting the machine in case of breakage.

Key Features:

Benefits:

The recent development has brought in modular cooling concepts for jet cooling & all other modes of mold cooling. These units can be mounted near the mold to reduce actuation time and drop in pressure. It is a one-stop solution for jet cooling, line cooling, and spot cooling. It delivers better process control. Raga Modular cooling state-of-the-art jet cooling machines also include closed looping and live monitoring.

Die for very high-tonnage die-casting machines such as Giga Press have large surfaces and more heat zones. Different forms of cooling are needed for different zones to achieve the desired solidification around core pins and thin sections. Modular cooling is the best solution for very high-tonnage die-casting machines.

All we need is a potential free shot signal from your die casting machine. The Jet Cooling machine kick starts once it receives the shot signal and then works as per recipe put in by you for your mold. We have done this with UBE, Toshiba, Frech, Buhler, Italpresse, Idra, LK, Zitai, Yizumi, Weingarten Muller, HMT and many more

Raga Jet Cooling machines are Plug and Play machines. With the installation manual, any engineer can connect the machine mechanically with the machine and mold in a single day. The user-friendly interface screen allows the user to run the machine effortlessly. Plus the installation videos on youtube with private access makes it easy for any new engineer to learn and do the installation. There is online support that is also given by Raga in such cases.

Raga machines are designed and manufactured with standard bought out parts that are available across the world and with service/spares backup. Very few non standard parts are stocked at Raga which can be air shipped. Also most customers keep inventory of critical parts as per list given by us to them. The machines are engineered to be simple in construction and working. Any engineer with basic knowhow and experience can do preventive and breakdown maintenance.

The jet cooling machines come with an optional Ethernet device that can help our service engineers to access your machine remotely and troubleshoot. There are troubleshooting videos that can be privately accessed from youtube which your engineer can use to troubleshoot himself. There is a troubleshooting guide on the machine screen also which generates alarm and indicates possible causes. In any case the manual has the troubleshooting steps which are user friendly.

Raga provides a 5 step guide for your design and application engineers to understand basic steps to convert your existing mold into a mold compatible for jet cooling systems. This guide helps in modification of core pins and selection of jet coolers. In any case, our team of application experts are there to help you suggest a solution that fits your needs

Our machines have been working across the world in languages like Polish, Spanish, Chinese, Korean and many more. On specific request, the machine is built with local language working screens. Manuals for installation and troubleshooting are also provided both in English and local language.