Did you know that porosity defects are responsible for up to 60% of quality issues in metal casting? These tiny

Porosity in casting is a critical issue that can significantly impact the quality and performance of cast components. Addressing these

Cold chamber die casting is a key process in modern manufacturing, particularly for producing high-quality metal parts. This method is

Core pins are the unsung heroes of the injection molding process. These small but mighty components are essential for creating

Die casting is a widely used manufacturing process that shapes molten metal into precise, complex parts by injecting it under

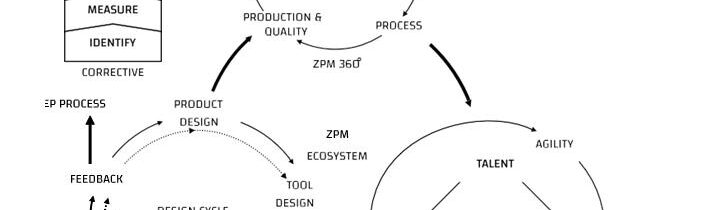

Die casting technology is at the heart of manufacturing, producing precise metal parts for sectors ranging from automotive to aerospace.

What is Die Casting? cooling solution for die casting – In die casting, a molten metal is injected or poured

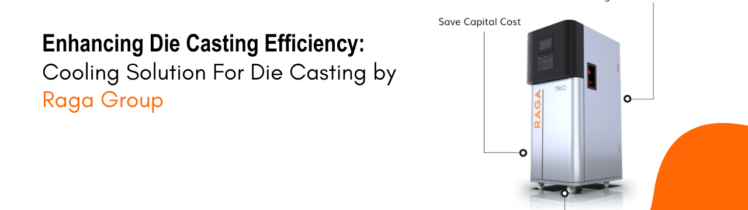

Closed-Loop Jet Cooling: Transform your die-casting processes with the cutting-edge closed-loop jet cooling technology. Harness the power of water recycling

Are you ready to embark on a transformative journey in the world of die casting? Allow us to introduce you

Porosity management is a critical concern in the die casting industry, affecting the quality, integrity, and profitability of manufactured parts.