Permanent die casting is a versatile and efficient manufacturing process used to produce high-quality metal components with excellent precision and

Die extrusion is a versatile manufacturing process that shapes materials into precise cross-sectional profiles, playing a transformative role in industries

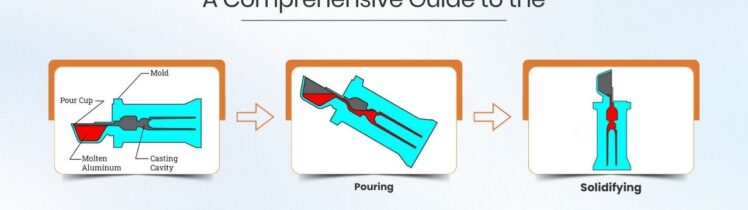

Gravity casting is one of the oldest and most dependable metal casting techniques, known for its precision, durability, and cost-effectiveness.

Centrifugal die casting is transforming the manufacturing industry with its unparalleled precision, strength, and efficiency. By harnessing the power of

Precision machining plays a crucial role in the casting industry, ensuring high-quality and accurate components for various applications. This blog

In the manufacturing industry, precision and efficiency are crucial, especially in die casting. Hot casting plays a significant role in

Casting alloys play a vital role in die casting, ensuring the production of durable, high-quality components. Their unique properties significantly

Die casting plays a crucial role in modern manufacturing, providing high-quality metal components with precision and efficiency. This blog explores

In the competitive world of modern manufacturing, precision is not just a requirement, it’s a necessity. Precision core pins are

Precision is the cornerstone of die casting, where even minor imperfections can lead to costly defects. Did you know that