Unlocking the Challenges of Porosity Management in Die Casting

Porosity management is a critical concern in the die casting industry, affecting the quality, integrity, and profitability of manufactured parts. In this blog, we’ll delve into the complex world of porosity in die casting, shedding light on its significance, dispelling common myths, and exploring real-world implications.

Porosity: A Pervasive Challenge

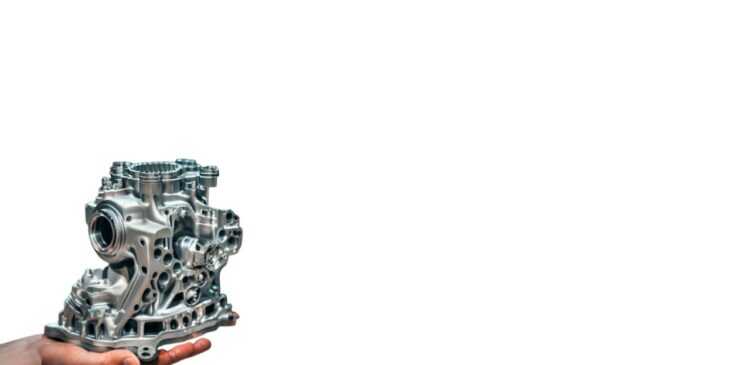

Imagine meticulously crafting components for industries such as automotive, aerospace, or electronics, only to have them rejected due to excessive porosity. Porosity, the presence of tiny voids or pores within a casting, is a prevalent issue in die casting with far-reaching consequences:

- Impact on Profitability: Porosity can lead to increased rejection rates, production delays, and higher costs, directly affecting a company’s financial health.

- Stringent Quality Standards: Industries like automotive and aerospace demand flawless parts. Failing to meet these quality standards can result in lost business opportunities.

- Lightweighting and Aesthetics: Modern manufacturing trends require precise control of porosity, especially in applications emphasizing lightweighting and aesthetics.

- Structural Integrity: In safety-critical industries like automotive, porosity compromises the structural integrity of components, posing significant risks.

Dispelling Porosity Myths

Before we explore porosity management, let’s debunk some common myths:

Myth #1: Porosity is an Expert-Only Subject

Porosity can be effectively managed by following proven steps accessible to the entire die-casting team.

Myth #2: No Trial Porosity Equals No Production Porosity

Trial conditions differ from production conditions, and porosity may surface during production due to various factors.

Myth #3: Only Major Interventions Control Porosity

Small changes and attention to detail can significantly reduce porosity.

Myth #4: Certain Factors Have Minimal Impact on Porosity

Factors like metal temperature, injection systems, die maintenance, and cooling play crucial roles in porosity management.

Myth #5: Only Specific Roles Control Porosity

While design, quality, and root cause analysts contribute, porosity control is a collective responsibility.

Myth #6: Porosity Control is Highly Subjective

In most cases, porosity stems from common sources, allowing for systematic control measures across products.

Myth #7: No Structured Approach Exists for Porosity Control

Structured frameworks and checklists can effectively minimize porosity.

Myth #8: You Need a “Porosity Doctor”

Porosity control demands adherence to established processes rather than the expertise of a specialist.

Myth #9: Mold and Machine Condition Are Irrelevant to Porosity

Machine and mold conditions, including age and maintenance, significantly impact porosity.

The Bottom Line on Porosity

Porosity management is a multifaceted challenge with profound implications for die-casting businesses. By dispelling myths and embracing systematic approaches, companies can enhance profitability, meet stringent quality standards, and ensure the integrity of their products.

Stay tuned as we continue to explore die casting, its challenges, and strategies for success. For further insights, check out the book “Mastering Die Casting – Porosity Management” by Rahat A. Bhatia, a comprehensive guide to conquering porosity in the die casting industry.