Achieving Die-Casting Excellence: Unveiling the Secrets of Porosity Control

When it comes to the world of die casting, achieving the elusive “zero porosity” might be a myth, but minimizing porosity is a very achievable goal. In his groundbreaking book, “Zero Porosity Management,” Rahat A Bhatia takes a deep dive into the management side of controlling and managing porosity, shedding light on crucial considerations that can transform your die-casting business. In this SEO-optimized blog post, we’ll explore key insights from the book, all while keeping the book and author in focus for those essential search engine rankings.

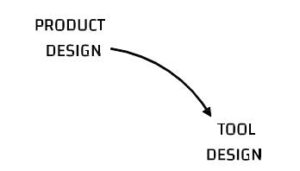

Porosity Control Begins with Product Design

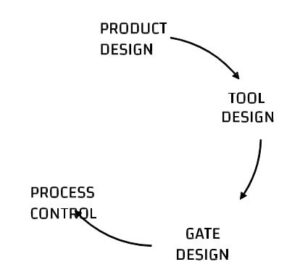

One of the first stages where porosity control must be addressed is at the product design phase. Ignoring this can lead to a cascade of issues, including rework and longer manufacturing times. To minimize shrinkage porosity, designing it out of the product is the most cost-effective approach. Rahat A Bhatia highlights that several aspects of die-casting significantly affect shrinkage porosity. These include alloy selection, thickness and stock consistency, core pin depth, and the angle of features inside the casting. Achieving directional solidification is essential to minimize shrinkage porosity, and it all starts with the product design.

One of the first stages where porosity control must be addressed is at the product design phase. Ignoring this can lead to a cascade of issues, including rework and longer manufacturing times. To minimize shrinkage porosity, designing it out of the product is the most cost-effective approach. Rahat A Bhatia highlights that several aspects of die-casting significantly affect shrinkage porosity. These include alloy selection, thickness and stock consistency, core pin depth, and the angle of features inside the casting. Achieving directional solidification is essential to minimize shrinkage porosity, and it all starts with the product design.

Mastering Tool Design for Porosity Control

Tool or mold design is a critical process in controlling porosity levels and their positions. Thermal balancing of the mold, venting, and die temperature measurement play vital roles in controlling both shrinkage and gas porosity. Rahat A Bhatia points out key aspects of tool design, such as internal cooling, venting, and core pin depth, all of which can significantly impact porosity. The book stresses the importance of maintaining consistent die temperature, ensuring smooth radius and corners, and appropriate vent sizing and location to mitigate gas porosity.

Tool or mold design is a critical process in controlling porosity levels and their positions. Thermal balancing of the mold, venting, and die temperature measurement play vital roles in controlling both shrinkage and gas porosity. Rahat A Bhatia points out key aspects of tool design, such as internal cooling, venting, and core pin depth, all of which can significantly impact porosity. The book stresses the importance of maintaining consistent die temperature, ensuring smooth radius and corners, and appropriate vent sizing and location to mitigate gas porosity.

Gating and Process Control

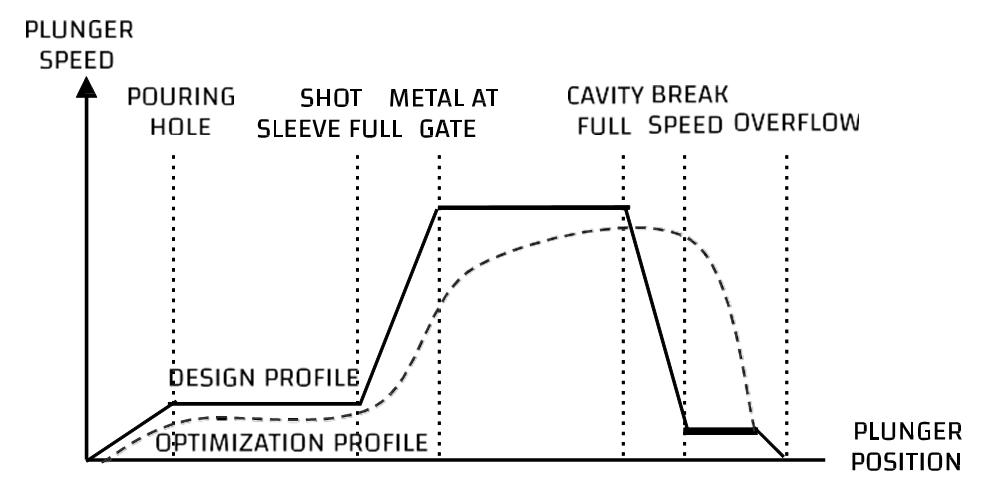

Porosity can also be influenced by gating and process control factors. Rahat A Bhatia dives into the intricacies of gate design, discussing aspects like gate thickness, distance from the gate, fill time, and gate velocity.

The book explains how feeding critical sections directly and maintaining the right gate thickness-to-casting thickness ratio can drastically reduce porosity. Additionally, it covers cycle element timing, shot end variables, plunger profiles, and the critical role of lubricants and die release agents in porosity control.

The ZPM Framework: A Path to Consistent Porosity Control

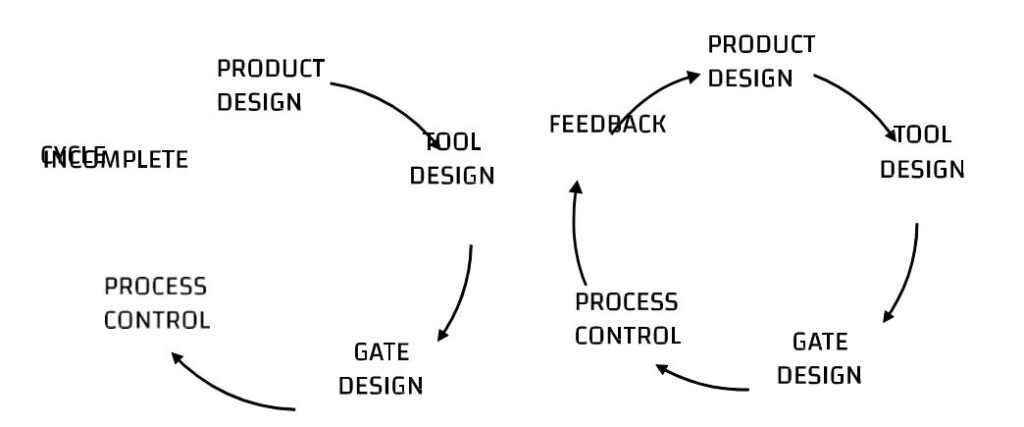

Rahat A Bhatia recognizes that the challenge for every die caster lies in putting all these considerations into one measurable and controllable framework. Enter the Zero Porosity Management (ZPM) framework. This framework, introduced in the book, empowers your team to minimize porosity consistently, regardless of the die-casting job at hand. It provides a holistic approach to defining and maintaining input parameters in die-casting environments to achieve casting quality with near-zero porosity.

Rahat A Bhatia recognizes that the challenge for every die caster lies in putting all these considerations into one measurable and controllable framework. Enter the Zero Porosity Management (ZPM) framework. This framework, introduced in the book, empowers your team to minimize porosity consistently, regardless of the die-casting job at hand. It provides a holistic approach to defining and maintaining input parameters in die-casting environments to achieve casting quality with near-zero porosity.

Conclusion

“Zero Porosity Management” by Rahat A Bhatia unveils a world of possibilities in porosity control for die casting. It goes beyond the technicalities and delves into the management aspects, making it an indispensable resource for those looking to enhance their die-casting processes. With a focus on product design, tool design, gating, and process control, coupled with the power of the ZPM framework, this book equips you to embark on a journey towards consistent and effective porosity control.

Ready to transform your die-casting business? Dive into “Zero Porosity Management” and discover how to master the art of porosity control.

Order Your Copy and start your journey towards near-zero porosity today.

Stay tuned for more insights from the book and practical tips for optimizing your die-casting processes.